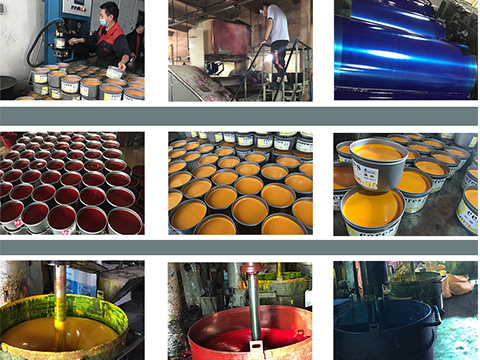

Ceres Mackintosh&Roller Washing

Brand Ceres

Product origin Guangdong,China

Delivery time 3-5 Days

Supply capacity 200-1000pcs/week

Blanket reducer is a chemical designed for the printing industry, mainly used to restore the elasticity and flatness of the rubber blanket, and remove dirt and oxides on its surface. By using the rubber blanket reducer, the service life of the rubber blanket can be effectively extended, the printing quality can be improved, and the production cost can be reduced.

Mackintosh&Roller Washing is a chemical designed for the printing industry, mainly used to restore the elasticity and flatness of the rubber blanket, and remove dirt and oxides on its surface. By using the rubber blanket reducer, the service life of the rubber blanket can be effectively extended, the printing quality can be improved, and the production cost can be reduced.

Working principle of rubber blanket wash.

During the printing process, the rubber blanket will be affected by ink, water, paper and other substances, resulting in surface hardening and depression, which will affect the printing quality. The active ingredients in the rubber blanket reducer can penetrate into the interior of the rubber blanket, soften the hardened rubber molecules, fill the concave parts, and dissolve the dirt, so that the rubber blanket is restored to a state close to that of the new one.

Efficacy of rubber blanket reducer

·Restore elasticity: Restore the elasticity of the hardened rubber blanket and improve the efficiency of printing pressure transmission.

·Flatten the surface: Fill the concave parts to make the printing surface smoother and the printed image clearer.

·Remove dirt: Dissolve dirt such as ink and paper scraps to extend the service life of the rubber blanket.

· Anti-oxidation: Form a protective film on the surface of the rubber blanket to prevent oxidation and extend its service life.

Types of rubber blanket reducing agents

Rubber blanket reducing agents can be divided into many types according to their composition and performance, the common ones include:

· Water-based reducing agent: With water as solvent, it is environmentally friendly and non-toxic, and suitable for all types of rubber blankets.

· Oil-based reducing agent: With organic solvent as solvent, it has strong dissolving power and is suitable for heavily polluted rubber blankets.

· Composite reducing agent: Combining the advantages of water-based and oil-based components, it has stronger cleaning and protection capabilities.

How to use rubber blanket reducing agent

1. Cleaning the rubber blanket: Clean the rubber blanket with clean water or a suitable cleaning agent to remove surface dirt.

2. Apply reducing agent: Apply the reducing agent evenly on the surface of the rubber blanket and wipe it with a soft cloth.

3. Let it stand: According to the product instructions, let it stand for a while to allow the reducing agent to fully work.

4. Cleaning: Rinse the rubber blanket thoroughly with clean water to remove the residual reducing agent.

Precautions

· Choose a suitable reducing agent: Choose a suitable reducing agent according to the material and degree of pollution of the rubber blanket.

· Use strictly according to the instructions: Avoid excessive use or prolonged contact to avoid damaging the rubber cloth.

· Operate in a well-ventilated environment: Some reducing agents have a pungent odor, so pay attention to ventilation.

· Wear protective gloves and masks: Prevent chemicals from irritating the skin and respiratory tract.

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If not reached behind MOQ quantity,proofing fee will be taken by you....more