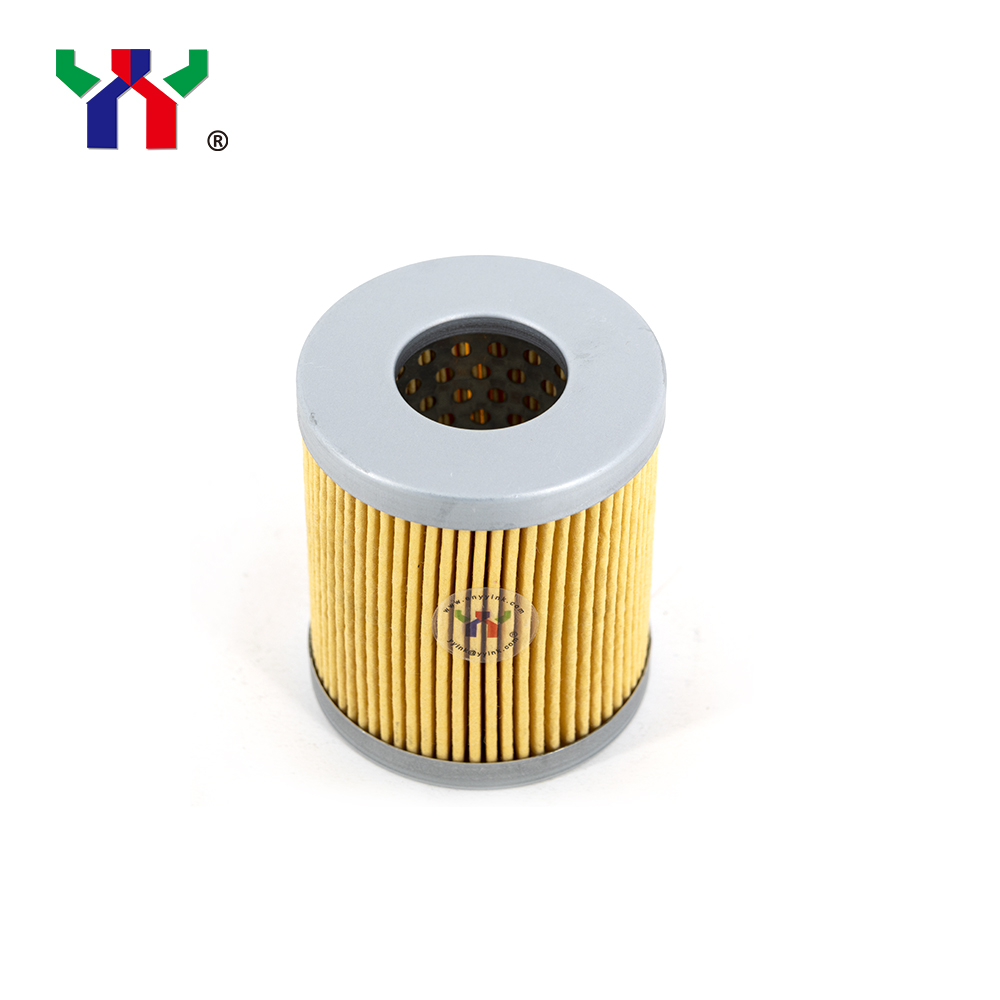

Air Filter (1)

The air filter element is a filter, also called air filter, air filter, style, etc. It is mainly used for air filtration in engineering locomotive, car, agricultural locomotive, laboratory, sterile operation room and various precision operation rooms.

During the working process, the engine should be suck into a large amount of air. If the air is not filtered, the dust suspended dust in the air is inhaled into the cylinder, and the wear of the piston group and the cylinder will be accelerated. Between the large particles entering the piston and the cylinder, it will cause a serious "pull cylinder" phenomenon, which is particularly serious in the dry and sandy working environment. The air filter is installed in front of the carburetor or the intake pipe, which plays the role of filtering the dust and sand particles in the air to ensure that the amount of air enters a sufficient amount of air in the cylinder.

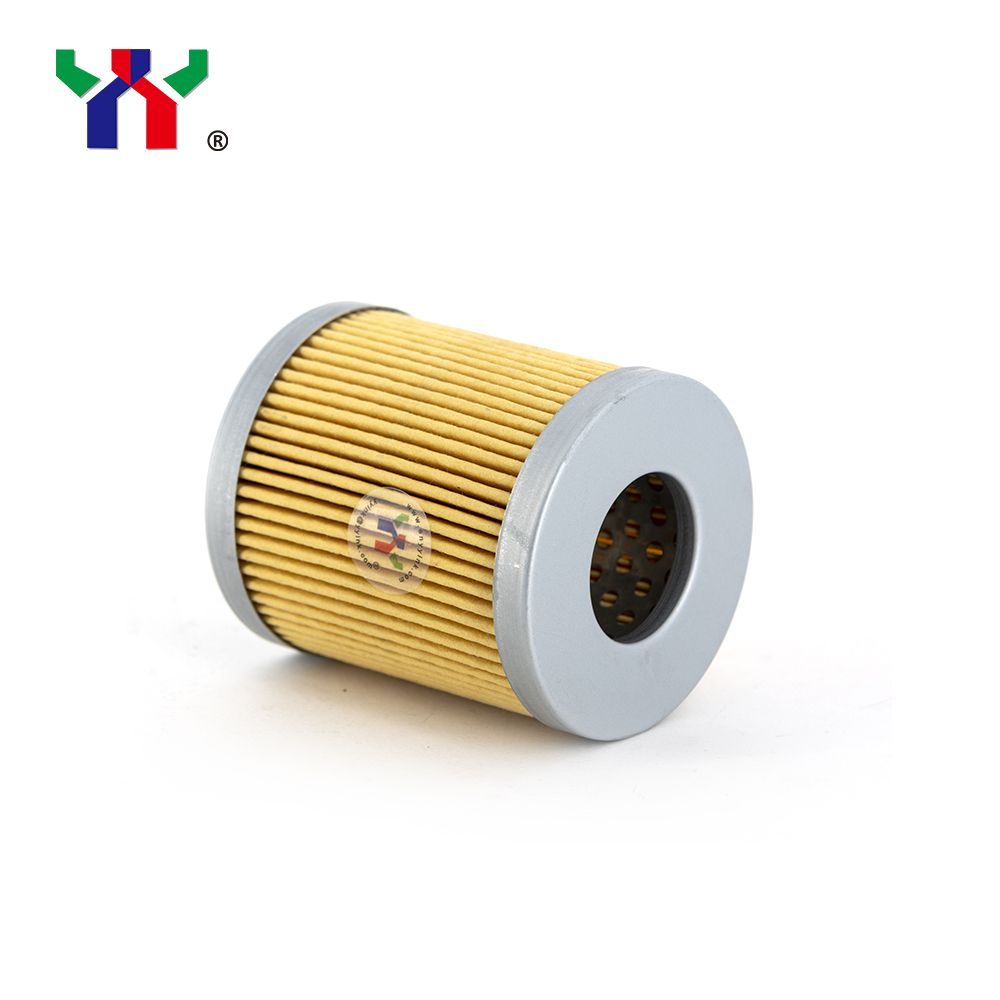

Type of air filter

According to the principle of filtering, the air filter can be divided into filtration, centrifugal, oil bath, and composite. The air filters commonly used in the engine include inertial oil bath air filter, paper dry air filter, polyurethane filter air filter. The inertial oil bath air filter has been filtered through the three -level filtering of the three -level filtering through inertia filtering, oil bath filtering, and filter filtering. The latter two air filters are filtered through the filter element. The inertial oil bath air filter has the advantages of small intake resistance, can adapt to the dusty and sandy working environment, and long service life. It used to be used on a variety of models of cars and tractor engines. However, this air filter filtering efficiency, large weight, high cost, and inconvenient maintenance, have gradually been eliminated in automotive engines. The filter element of the paper dry air filter is made of micropiced filter paper treated by the resin. The filter paper pores, loose, folding, have a certain mechanical strength and water resistance, have high filter efficiency, simple structure, light weight, cost, cost, cost The advantages of low and convenient maintenance are currently the most widely used automotive air filter. The filter element of polyurethane filter element air filter is made of soft, porous, sponge -like polyurethane. It has a strong adsorption ability. This air filter has the advantages of paper dry air filter, but the mechanical strength is low. It is widely used. The disadvantage of the latter two air filters is that the service life is relatively short, and the work is unreliable under harsh environmental conditions.

Advantages and disadvantages

Various air filters have advantages and disadvantages, but there are contradictions between the amount of air intake and filtering efficiency. With the in -depth study of the air filter, the requirements for the air filter are getting higher and higher. Some new air filters have appeared, such as fibrous filter element air filter, duplex filtering material air filter, sound -mucking air filter, constant temperature air filter, etc. to meet the engine work.

Installation

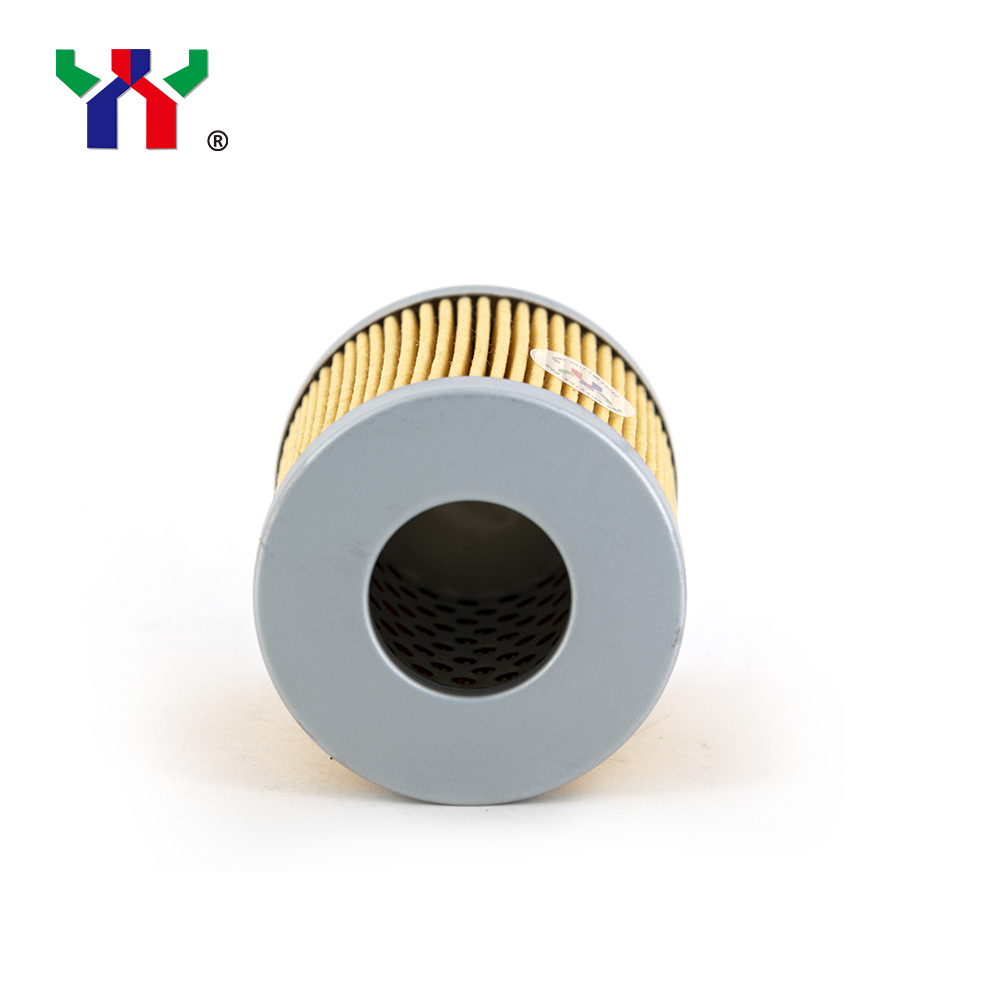

1. During installation, whether the air filter and the engine of the engine are connected or directly connected, whether the flange or rubber pipe is connected or directly connected, it must be strict and reliable to prevent the gas leakage. The wing nuts of the outer cover cannot be twisted too tightly to avoid crushing the bad paper filter element.

2. During maintenance, the paper filter element must not be cleaned in the oil, otherwise the paper filter element will fail, and it will easily cause a speeding accident. During maintenance, you can only use the vibration method, soft brush method (to follow its wrinkles) or compress the air anti -blowing method to remove dust and dirt attached to the surface of the paper filter element. For the dusty filter part, the dust collection parts, leaves and cyclones should be removed in time. Even if you can carefully maintain each time, the paper filter element cannot fully restore the original performance, and its intake resistance will increase. Therefore, when the paper filter element needs to be maintained for the fourth maintenance, the new filter element should be replaced. If the paper filter element has problems such as rupture, perforation, or filter paper and end covering, it should be replaced immediately.

3. When using it, it is necessary to strictly prevent the paper core air filter wet by rain, because once the paper core adsorbs a lot of water, it will greatly increase the intake resistance and shorten the mission. In addition, the paper core air filter cannot be contacted with oil and fire.

4. Some vehicles are equipped with a whirlwind air filter, and the plastic cover of the paper filter element end is a diversion cover. The blades on the hood rotate the air. 80%of the dust is separated under the action of centrifugal force. The dust that reaches the paper filter element is 20%of the amount of inhalation of dust, and the total filtering efficiency is about 99.7%. Therefore, when maintaining a whirlwind air filter, be careful not to miss the plastic diversion cover on the filter element.

Print Area is professional in printing industry 20+ years.

Security Paper:Watermark Paper,UV Fiber Paper,Thread Paper

Security Ink:OVI,UV Invisible Ink,Magnetic Ink,Water Sensitive Ink,Watermark Ink,Glow in Dark Ink

Offset Ink:Soy Bean Offset Ink,UV Offset Ink

Printing Materials:PS Plate,Rubber Blanket,Underpacking Foil,Underpacking Paper.

Machine:Die Cutting Machine,Offset Machine,UV Flexo Machine,UV Coated Machine ect.

Please don’t wait and contact with

Caroline:+8618026391301(wechat & whatsapp avaliable.)

Email:fluorescentink@yyink.com

Web:www.printarea.cn