Offset Rubber Blanket (3)

Matters needing attention during the use of the Rubber blanket

When installing the blanket, pay special attention to the fact that the cushion should not have any wrinkles. Under normal circumstances, blanket + felt + paper; or blanket + worsted wool + paper. Felt, worsted wool, paper and other lining materials, if you don't pay attention to it, they will tend to wrinkle if they are not spread evenly.

When tightening the rubber cloth, drag the tip and bite both sides at the same time, do not tighten it on one side. Pay attention to safety during operation, and avoid inserting tools and screws into the roller and crushing the blanket.

The new rubber cloth has good elasticity and good stretchability. The tensioning of the rubber cloth should be done gradually, and the tension should be performed once, and then the tension should be tightened after the offset printing press is pressed for 3~5min, so that it can be repeated 2~3 times to achieve the tightening requirements.

Whether the blanket and its liner are flat, if there are ink skins, paper scraps and sundries in the blanket, there will be convex and concave phenomena, and the blanket should be reinstalled.

Before installing the blanket, the thickness of the blanket + felt or worsted wool + paper should be accurately measured with a micrometer, and the four sounds of the micrometer should be measured. Soft lining: blanket + felt + paper, lining thickness: 3.35~3.45mm. Neutral lining: blanket + worsted wool + paper or blanket + paper, lining thickness: 3.20~3.25mm. Rigid lining: blanket + insulating paper or photo paper, lining thickness: 3.18-3.20mm.

Blanket cutting requires rectangular correctness. Only when the warp direction of the blanket is selected as the direction of cutting, tightening and bearing tension can the desired effect be obtained. By observing the cylindrical shape of the natural roll, the warp and weft direction can be known. The thread parallel to the core line of the natural roll should be the weft direction, and the direction perpendicular to the weft thread should be the warp direction. It is mainly judged based on the threads of the plain weave on the reverse (back) surface of the blanket.

The lining paper in the blanket lining should be shorter than that of the blanket to prevent moisture from penetrating into the paper fiber and swell and deform when exposed to water, and reduce the rust and erosion of the roller.

The rubber cloth is an elastic object, and it will inevitably produce elongation after being stressed during the entire clamping, transmission and imprinting process. In order to transfer the size of the graphics on the printing plate to the paper more accurately, the elongation of the blanket must be small during the entire embossing process, and it must be uniform.

The above-mentioned elongation is not only related to the quality of the blanket itself, but also depends on the degree of tightness of the blanket on the drum. The tighter the blanket, the better? Of course this is not the case in actual work. The blanket should be stretched properly.

①The tighter the blanket is, the less the elongation in the printing process will be, and the change in the size of the picture and text will be smaller. However, if the leather cloth is too tight, it will lead to an increase in the amount of friction on the plate and a decrease in the life of the printing plate.

②If the blanket is stretched too loosely, then the stretch rate of the blanket will increase, and the amount of friction on the layout will decrease, which will easily cause double printing (ghosting).

The quality requirements of the blanket

In the offset printing process, the function of the blanket is to transfer the pictures and texts on the printing plate to the substrate paper completely and clearly. In order to strive for the perfect transfer of images and texts, the blanket must have the following characteristics:

The blanket thickness should be even

The uniform thickness will make the printing pressure evenly distributed, and the ink color will be more even when printed, and the size of the image and text is not easy to change during the process of image and text transfer.

Has good flexibility

Ordinary solid rubber cloth has good elasticity. The effect of image and text transfer and ink absorption performance may also be good. During the embossing process of ordinary solid rubber cloth, the surface rubber layer often produces convex hulls at the leading edge of the embossing line. According to the inference of the embossing principle, hard rubber The cloth will not shrink in volume under pressure, so it can only be squeezed to both sides of the embossing line. However, if you choose to use an air cushion blanket, there will be no problem of convex hulls at the leading edge of the embossing line.

The blanket has a small elongation

The compact structure and high mechanical strength of the blanket are beneficial to increase the tensile strength and reduce the deformation of the image and text transfer.

Good ink absorption and transfer performance

It can ensure that the ink is well-proportioned and the writing is clear during the printing process.

The rubber cloth has good oil resistance, abrasion resistance, heat resistance and anti-aging properties. It has all the above properties and can extend its service life.

In addition, it also has the properties of acid resistance, alkali resistance and corrosion prevention. The quality of the blanket is directly related to the quality of the graphic transfer. Although there are many factors that affect the quality of graphics and texts, including machinery, plate making, materials, and process control, the quality of the blanket is one of the important factors. Because the blanket is penetrated by gasoline, kerosene, and engine oil during the printing process, Due to pressure and relative friction between the roller and the roller, the blanket will be stretched, squeezed and deformed periodically, and the blanket will become sticky, deformed and lack good elasticity due to the loss of sulfur, which will affect the quality of the transfer. In this case , You have to replace the old blanket again.

Blanket storage environment requirements

1) The blanket should be stored in a cool, dry environment, and away from heat sources, avoid direct sunlight, to prevent aging and desulfurization. In order to ensure good air circulation, each blanket should be hung on the handle. If the warehouse is narrow, the blanket should be laid flat, and no heavy objects should be placed on it. It is best not to roll the blanket into a tube when storing it.

2) Open the packaging of the blanket, remove the protective cover, and carefully check whether the blanket is damaged. It is not advisable to install the new blanket directly on the machine. Because the blanket is rolled into a tube for packaging, it should be laid flat for a period of time, so that it can be used on the machine after it gradually becomes flat.

3) If a lot of blankets are stacked, they should be stacked face to face or back to back, otherwise the fiber pattern on the back of the blanket will affect the flatness of the other blanket.

4) Do not squeeze the blanket, so as not to break the blanket or damage its elasticity. The blanket is resistant to light, heat and humid air. They will cause sticky, crust, dry cracking, hardening and other defects on the surface of the blanket. .

5) The warehouse for storing blankets should be ventilated and dry, with a relative humidity of about 70%, and a temperature of about 24°C. Keep the blankets away from acids, alkalis, oxidants, and petrochemical products to avoid chemical erosion of the blankets.

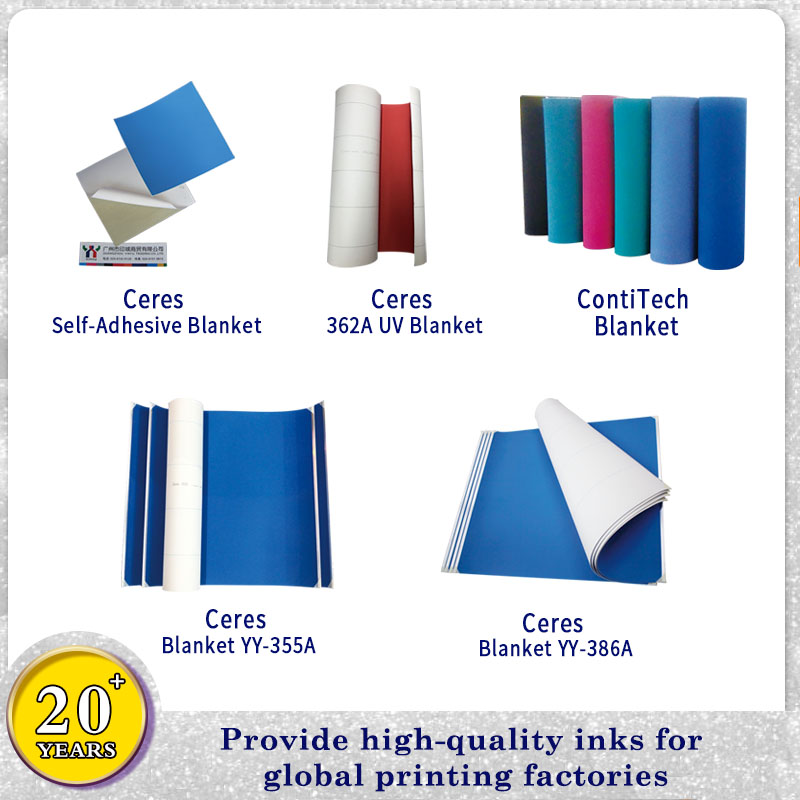

Print Area is profesional at any kinds of ink and printing materials,which has more than 20 years in printing market.

Offet/Screen/Flexo Printing Ink

Security Ink:OVI,UV Invisible Ink,Pearl Ink,watermark ink,magnetic ink,scratch off ink,infrared absorb ink,solar sensitive ink,glow in dark ink,mirror ink,conductive ink,glass ink,perfume ink and so on.

Welcome to send us inquiry.

Caroline:+8618026391301(wechat/whatsapp available).