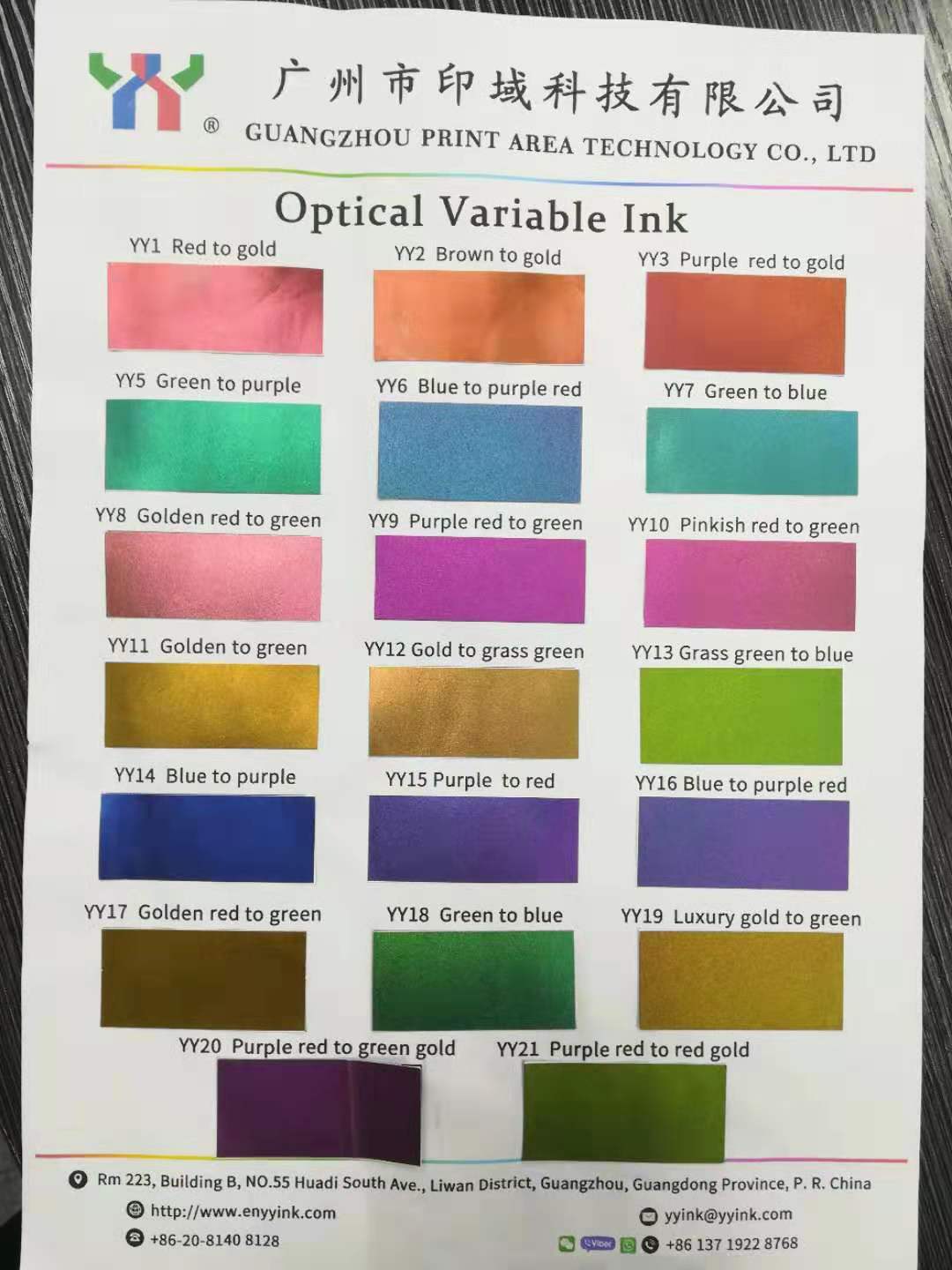

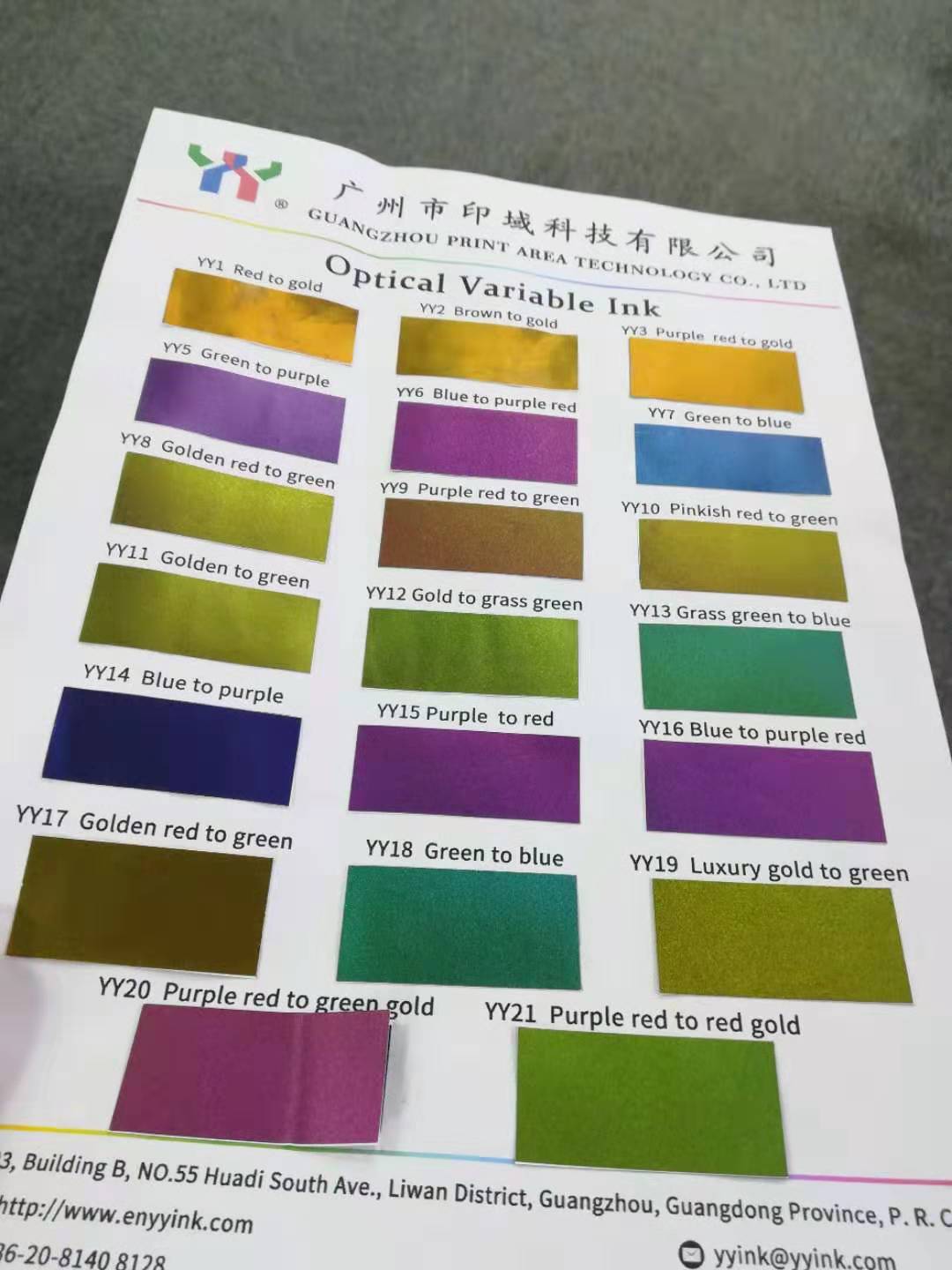

Optical Variable Ink

Optical variable ink is also called optical color-changing ink and chameleon. The printed product color block presents a pair of colors, such as red-green, green-blue, gold-silver and so on. When looking directly or sideways under white light, as the human eye's viewing angle changes, it presents two different colors. The light change characteristics are strong, the chromatic aberration changes greatly, and the characteristics are obvious. It can be recognized without any equipment and the color angle effect is impossible. Reproduced with any high-definition scanner, color copier and other equipment, the printing features cannot be imitated by any other ink and printing method, and the anti-counterfeiting reliability is extremely strong, so it is designated by many countries in the world for the most stringent and difficult requirements. For the anti-counterfeiting of the largest currencies and securities, some well-known domestic manufacturers have also used packaging anti-counterfeiting.

Classification

Optically variable materials are widely used in the field of printing inks. According to their different uses, there are water-based inks, ink-based inks, plastic inks, and interference inks.

Production method

The manufacturing method of this kind of ink is generally to dissolve the photochromic pigment in a solvent to form a microformed pigment capsule, and add a binder to the dissolved pigment according to different uses. A better manufacturing method is to dissolve photochromic pigments into superimposed monomers, pulverize such polymer ultrafine particles, and make powders for use as pigments. Compared with microcapsule inks, the inks made by this method are light-resistant Increased sex by 10 times. These powders can be used as pigments in water-based inks, oil-based inks, plastic inks, and all adhesives.

Photochromic water-based screen printing ink

Because of its safe use and convenient operation, it takes the lead in the fiber product industry. Use this water-based ink with 80-120 mesh screen printing, dry at 100°C for 1 min (preferably overnight), and then heat and bridge reaction at 130°C for 3 min to obtain excellent fiber adhesion. Products. The characteristics of this water-based ink are as follows:

Anti-counterfeiting numbers printed with optically variable ink

*The color can be developed quickly in the sun, and the colorless state can be restored in a short time after shading (different colors have different colors, yellow can be completed in an instant after 2 to 3 minutes);

*Dispersion performance, can get uniform color printing;

*Good color rendering and friction fastness;

*This water-based ink is a liquid type ink;

* Good storage stability and easy operation.

Photochromic oil-based ink

Mainly used for surface printing on plastic films and metal plates. This ink is printed with 100-200 mesh screen printing. There are many resins used in adhesives: acrylic, epoxy, urethane, silicone modified resin and so on. As solvents, there are esters, ketones, etc., as well as mineral turpentine and petroleum. Adding photochromic materials to these adhesives composed of resin and solvent can appropriately adjust the viscosity of the screen printing ink to make an oil-based screen printing ink.

Photochromic plastic ink

According to the survey, there are few printing companies using plastisol screen printing inks in Japan. However, in some countries such as the United States, especially the T-shirt production industry, this printing ink is used. As a kind of ink that is not easy to dry, plastic ink often does not need to clean the screen printing plate, and the ink remaining on the plate can also be used the next day. This kind of plastic ink is made into screen printing ink by using DOP plasticizer to expand the ultrafine powder of vinyl acetate copolymer. Photochromic pigments can also be added to this plastic polymerizer to make screen printing inks. However, when the characteristics of the photochromic material itself are suppressed, the photochromic pigment itself is completely decomposed. This phenomenon can only be manifested after several days. Therefore, it is difficult to use it as a commercial product.

But if the plastic resin does not use vinyl acetate copolymer, but uses an ultra-fine powder material with the same characteristics and can control the degeneration of the photochromic pigment, then it will be an ideal powdery photochromic plastic ink.

Interference ink

This kind of ink is the most complicated kind of modern anti-counterfeiting ink, and it is a popular high-tech product. Optically variable ink is a kind of reflective ink with pearlescent and metallic effects, which cannot be copied by color copiers and electronic copiers. For products printed with optically variable ink, the ink color block presents a pair of colors. Such as magenta-blue, green-blue, cyan-green, etc. If the pattern is tilted to 60°, the pattern can be transferred from one color to another. Since only when the ink film on the printed product is thicker can significant color drift occur, its printing characteristics cannot be imitated by any other inks and printing methods.