UV Invisible Ink: Preparation and Classification of UV Invisible Fluorescent Ink

【UV Invisible Ink】Preparation and Classification of Ultraviolet Fluorescence Invisible Ink

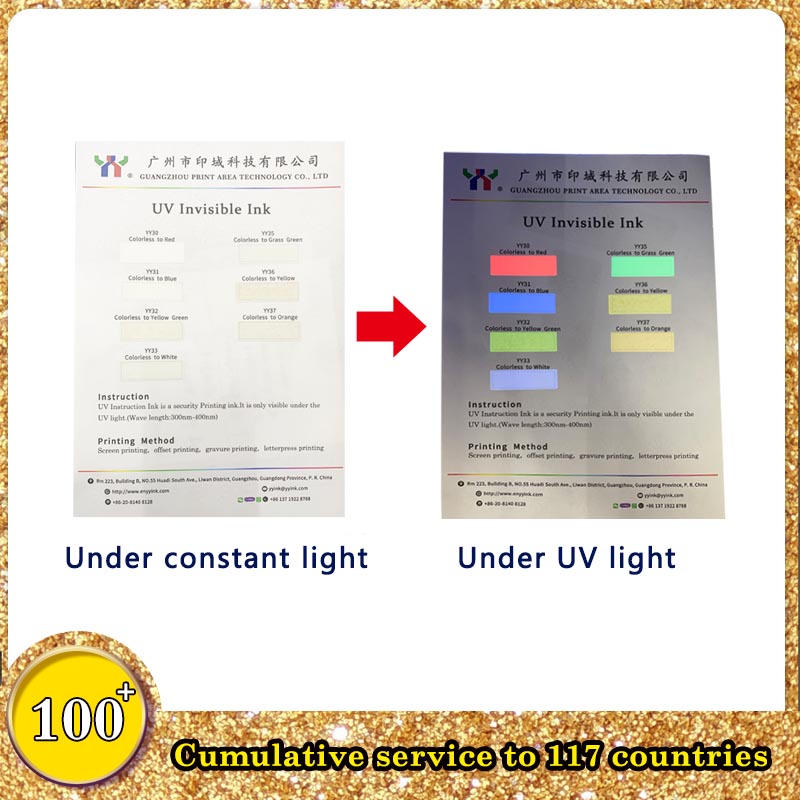

Ultraviolet-excited fluorescent anti-counterfeiting ink is an ink made of inorganic pigments or organic dyes that can be excited by ultraviolet light to display colors, called fluorescent inks (or invisible inks). Its manufacturing method is to add the pigment (dye) to a certain proportion of resin oil linking material, filler, stabilizer and desiccant, and process it with an ink-making three-roller mill.

According to Print Area Company, which supplies UV invisible inks and invisible powders:

According to whether the fluorescent ink has color or not, it is divided into two types: colored fluorescent ink and colorless fluorescent ink. The former is to add fluorescent compounds (complexes) into colored inks, while the latter is added to colorless oils: the printed graphics and texts of the former are visible to the naked eye, while the latter are invisible, but both need to be printed. Fluorescence can be displayed under ultraviolet irradiation. Under the irradiation of ultraviolet rays (200-400nm), inks that can emit visible light (400-800nm) can be divided into long-wave and short-wave inks according to the different excitation wavelengths of ultraviolet light when fluorescent colors are displayed. The excitation wavelength of 254nm is called short-wave ultraviolet excitation fluorescent ink, and the excitation wavelength of 365nm is called long-wave ultraviolet excitation fluorescent ink, which is more widely used. The identification method is to irradiate the printed product with ultraviolet light, and the colorless ink will display red, yellow, orange, green and other colors; colored fluorescent ink can make the original pattern appear more vivid; color-changing fluorescent ink can be illuminated by ultraviolet light. Make the print another color. No matter what kind of fluorescent ink its properties are very stable.

With good fluorescent materials, there must be good equipment, technology, and craftsmanship to prepare high-quality fluorescent inks. Because the manufacturing technology is not up to standard and the product quality is not up to standard, the quality of fluorescent inks in the domestic market is uneven, some are very unstable, and the fluorescence decays rapidly, so it cannot be used, so you should pay attention when purchasing.

Print Area is professional in printing industry 20+ years.

Security Paper:Watermark Paper,UV Fiber Paper,Thread Paper

Security Ink:OVI,UV Invisible Ink,Magnetic Ink,Water Sensitive Ink,Watermark Ink,Glow in Dark Ink

Offset Ink:Soy Bean Offset Ink,UV Offset Ink

Printing Materials:PS Plate,Rubber Blanket,Underpacking Foil,Underpacking Paper.

Machine:Die Cutting Machine,Offset Machine,UV Flexo Machine,UV Coated Machine ect.

Please don’t wait and contact with

Caroline:+8618026391301(wechat & whatsapp avaliable.)

Email:fluorescentink@yyink.com

Web:www.printarea.cn