-

Hot

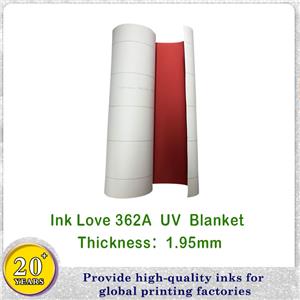

362 UV Offset Printing Rubber Blanket

UV rubber blanket reproduction will add anti UV resin components, UV resistant, rubber is not easy to powdered. UV rubber blanket is specially used for UV offset printing machine.It is suitable for 18000 speed offset printing machine. We can provide two kinds of packaging according to the needs of customers, one is one roll one carton ,another one is 1 pcs/carton .

Send Email Details -

Hot

UV Offset Led Ink Spot Color

With the popularization of technology and market competition, many traditional state-owned enterprises in China; the leading advantage of UVLED ink technology has gradually lost, and the cost advantages of other private enterprises have also revealed their market share. The current situation and development trend of UVLED ink in China are getting better and better. UVLED ink is an ink that can be cured instantly by ultraviolet radiation. The curing time is less than 1 second, and ordinary ink requires a high-energy-consuming drying device, which is very energy-saving. In addition, UVLEDf, Q ink contains pigments, acrylic prepolymers and monomers, photosensitizers and other components, so it is called an ideal non-toxic, non-polluting, energy-saving and environmentally friendly ink in the packaging industry. It is suitable for paper, cardboard, Packaging materials such as metal, glass, aluminum foil, plastic, etc.

Send Email Details -

Ceres UV Adhesive Rubber Blanket 100x90x0.35mm

A UV rubber blanket is a specific type of printing blanket used in UV offset printing presses. UV offset printing is a variation of offset printing that uses ultraviolet light to cure the ink. This allows for faster printing speeds and a wider variety of substrates to be printed on.

Send Email Details -

Hot

Screen Printing Mirror Ink Sliver

Mirror ink is a kind of solvent based ink with special effect. The ink is printed on transparent material on the back side to obtain mirror effect on the front side. Mirror ink is used in transparent materials, including PC (polycarbonate), PMMA (acrylic or plexiglass), hard PVC (polyvinyl chloride) and treated pet (polyester), glass, etc. Mirror ink only use for screen pritning ,screen mesh is 300mesh.

Send Email Details -

Hot

Gold Color Screen Printing Mirror Ink

Mirror ink is a kind of solvent based ink with special effect. The ink is printed on transparent material on the back side to obtain mirror effect on the front side. Mirror ink is used in transparent materials, including PC (polycarbonate), PMMA (acrylic or plexiglass), hard PVC (polyvinyl chloride) and treated pet (polyester), glass, etc. Mirror ink only use for screen pritning ,screen mesh is 300mesh.

Send Email Details -

Paper Stop for GTO46 52 Offset Printing Machine

Paper Stop is one kind of printing spare parts for the offset printing machine.Print Area supply thousands of parts to more than 600 countries from all over the world.More than 23 years we are in printing industry,here has 6000+ customers all over the world.

Send Email Details -

Hot

Red to Cololrless Infrared Absorption Ink for Screen/Offset Printing

IR ink that is invisible to the naked eye but when exposed to IR light appears as black to and IR camera.The appearance of light, infrared lens is dark, clear ink (no color), which absorb in the infrared .spectrum color, which are mixed.

Send Email Details -

Hot

YF-299 Food Grade Offset Ink

YF-99 food grade offset ink is made by Foshan Yinya Company.High-end quality requires printing books, pictorials, magazines, brochures, food packaging, etc. Features: High gloss High color density Quick dry Water and rub resistance

Send Email Details -

Hot

Offset Sublimation Ink

The patterns printed by the offset sublimation transfer process are rich in layers, bright colors, ever-changing, small color difference, good reproducibility, images will not fall off, crack and fade, and are wear-resistant and light-resistant, so sublimation heat transfer products are more durable advantage. Excellent ink balance, clear dot restoration, fast complete fixation, and stable on-board. It can achieve the effect of designing patterns and is suitable for mass wholesale production. The transfer process is processed by a heat transfer machine (heat and pressure) to transfer the exquisite pattern on the transfer film to the surface of the product. After the formation, the ink layer and the product surface are dissolved into One, lifelike and beautiful, greatly improving the grade of the product. Products that have been maturely developed using thermal transfer technology include: clothes, cloth bags, hats, pillows, mouse pads, coasters, pennants, mirror boxes, etc. hundreds of products.

Send Email Details