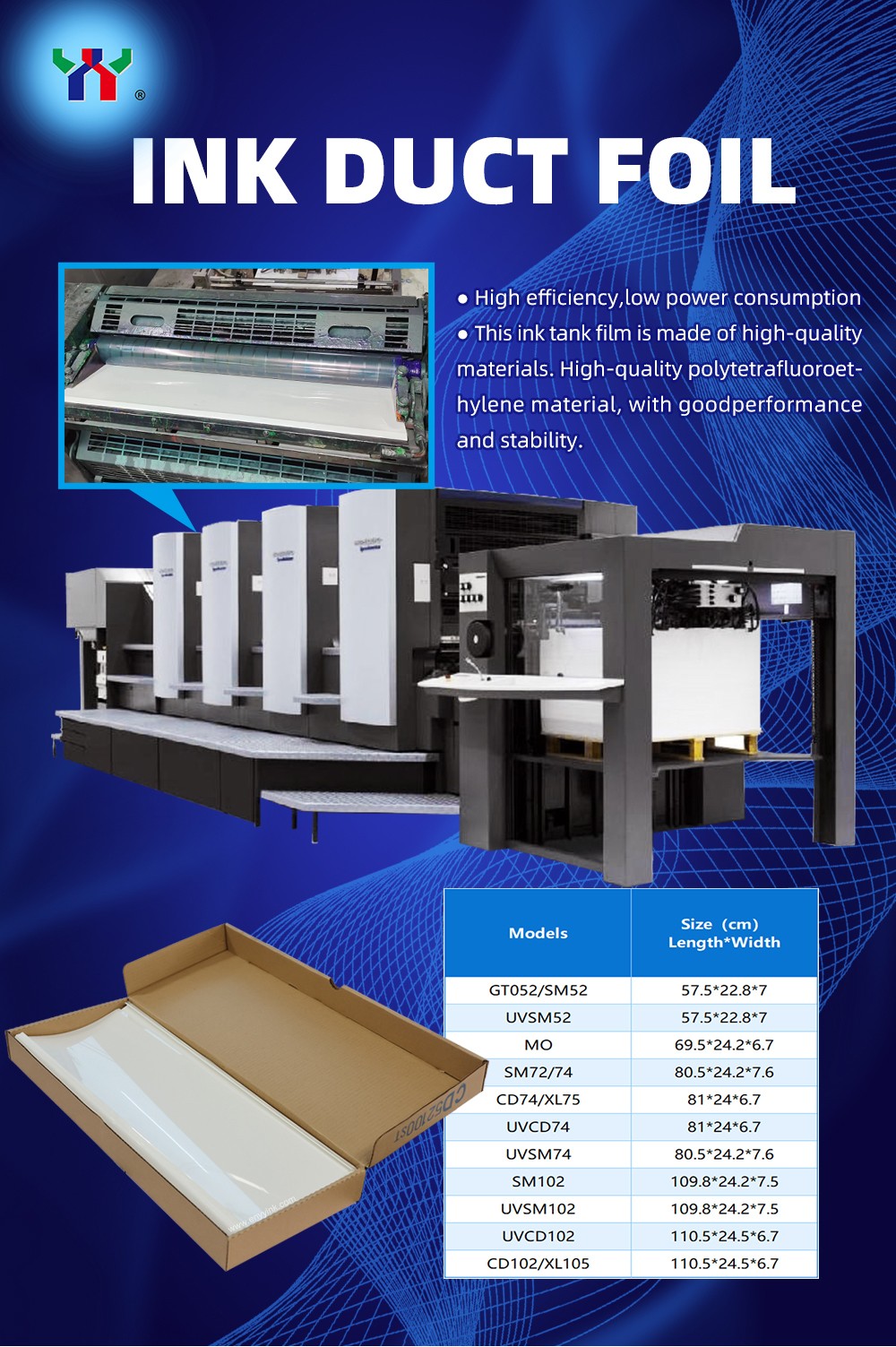

CD102 Ink Duct Foil 1067*228*0.188mm,100 pcs/carton

Brand Ceres

Product origin Guangdong,China

Delivery time Within 3 Days

Supply capacity 10000 box/week

The Heidelberg offset press ink duct foil is a high-precision consumable specifically designed for Heidelberg printing presses (such as the SM/CD/XL series). It is used to partition ink within the ink duct and control ink flow distribution, ensuring uniform ink dispersion, preventing color bleeding, and enhancing print color consistency and efficiency. It is an essential auxiliary material for high-quality printing.

Download

Product Name: Heidelberg Offset Press Specialized Ink Duct Foil (Ink Blade/Ink Partition Film)

Product Overview:

The Heidelberg offset press ink duct foil is a high-precision consumable specifically designed for Heidelberg printing presses (such as the SM/CD/XL series). It is used to partition ink within the ink duct and control ink flow distribution, ensuring uniform ink dispersion, preventing color bleeding, and enhancing print color consistency and efficiency. It is an essential auxiliary material for high-quality printing.

Key Features

High-Precision Compatibility

Strictly matches Heidelberg ink duct structures with precise dimensions (typically 0.1mm–0.3mm thick), ensuring seamless integration to prevent ink leakage.

Corrosion & Solvent Resistance

Made from specialized polymer or metal composite materials, resistant to long-term exposure to ink and cleaning solvents (e.g., gasoline, alcohol), preventing deformation or dissolution.

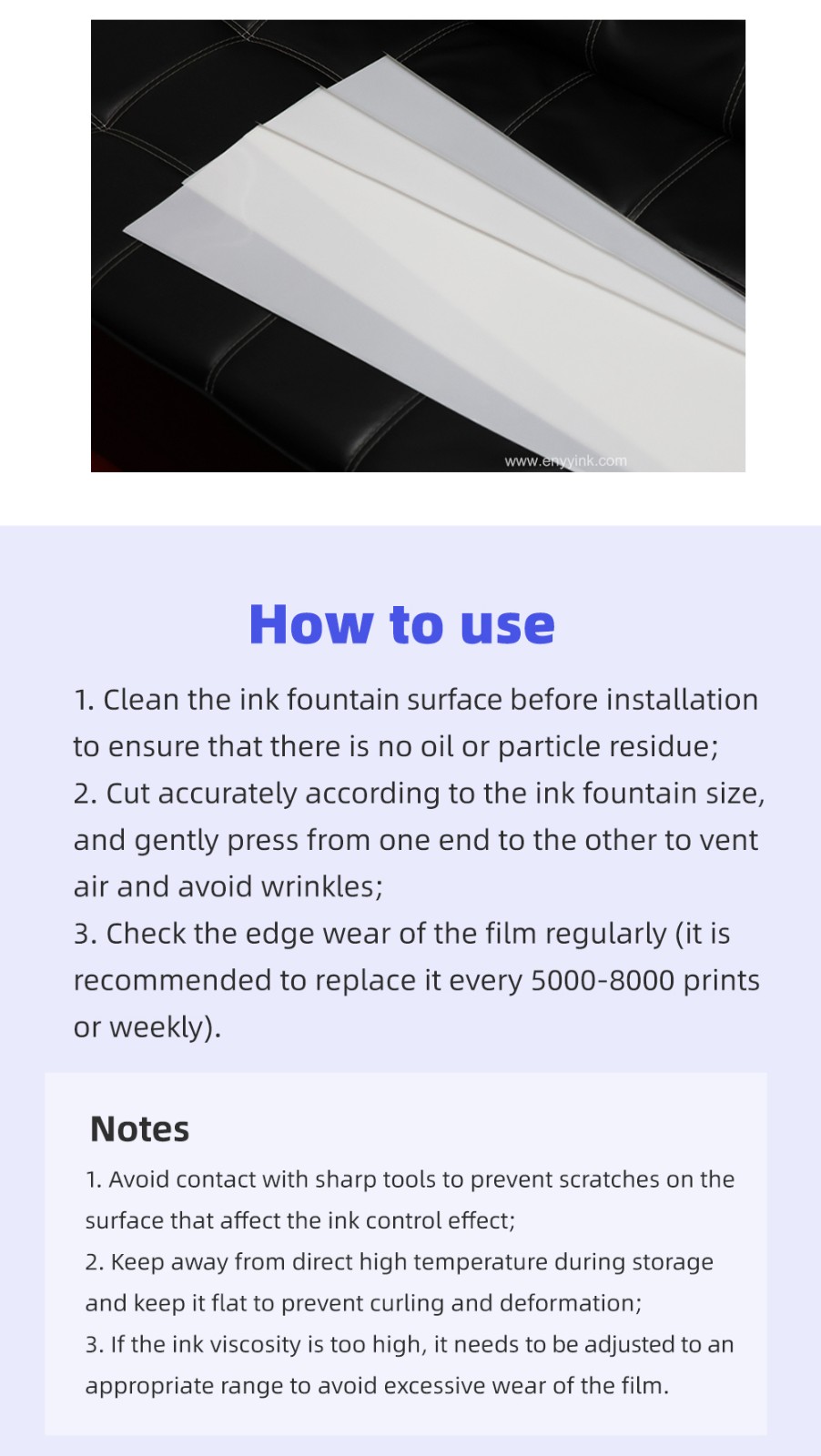

Flexible & Durable

High-elasticity material withstands repeated installation without breaking, with smooth edges to protect ink blade and roller surfaces.

Optimized Color Control

Minimizes cross-color contamination between ink zones, ensuring precise ink volume control for consistent print quality (meets ISO 12647 standards with ΔE ≤ ±0.1).

Compatible Models

Sheet-fed Presses: SM 52/74/102, Speedmaster CD/CX/XL series

Commercial Web Presses: M600/Heidelberg Web series

Other Compatible Models: Roland, KBA, and other presses with similar ink duct structures (size verification required)

Applications

Multi-color Printing: Isolates CMYK/spot colors to prevent mixing.

Long-run Jobs: Stabilizes ink output, reducing downtime for cleaning.

High-precision Printing: Packaging, art books, labels, and other color-critical prints.

Specifications

Parameter | Details |

Material | PET film/PTFE-coated |

Thickness | 0.1mm/0.15mm/0.2mm (customizable) |

Width | Customized per ink zone (e.g.,35mm/50mm) |

Length | Matches full ink duct length (e.g., 1020mm for SM102) |

Temperature Range | -20℃~150℃(higher for metal variants)(higher for metal variants) |

Usage Instructions

Pre-installation: Clean the ink duct to remove residual ink and debris.

Installation: Insert the film into the ink partition slot and press firmly to adhere to the duct base.

Replacement Cycle: Replace every 3–6 months or when visible wear occurs (varies by usage frequency).

Advantage Comparison

Conventional Generic Films | Heidelberg Specialized Ink Duct Films |

Prone to deformation/leakage | High stability superior sealing |

Frequent replacement needed | 50%+ longer lifespan |

Generic sizing poor fit | Precision-engineered for Heidelberg ducts |

Package:100 pcs/box