Fountain Solution for Offset Printing

Brand Ceres

Product origin Guangdong,China

Delivery time 5-7 days

Supply capacity 1-100 ton

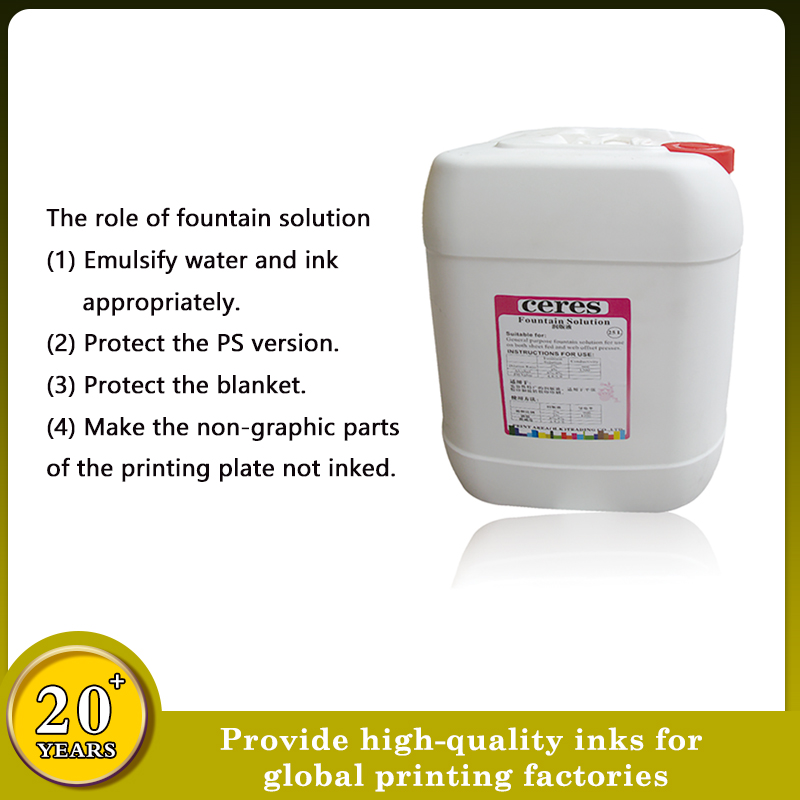

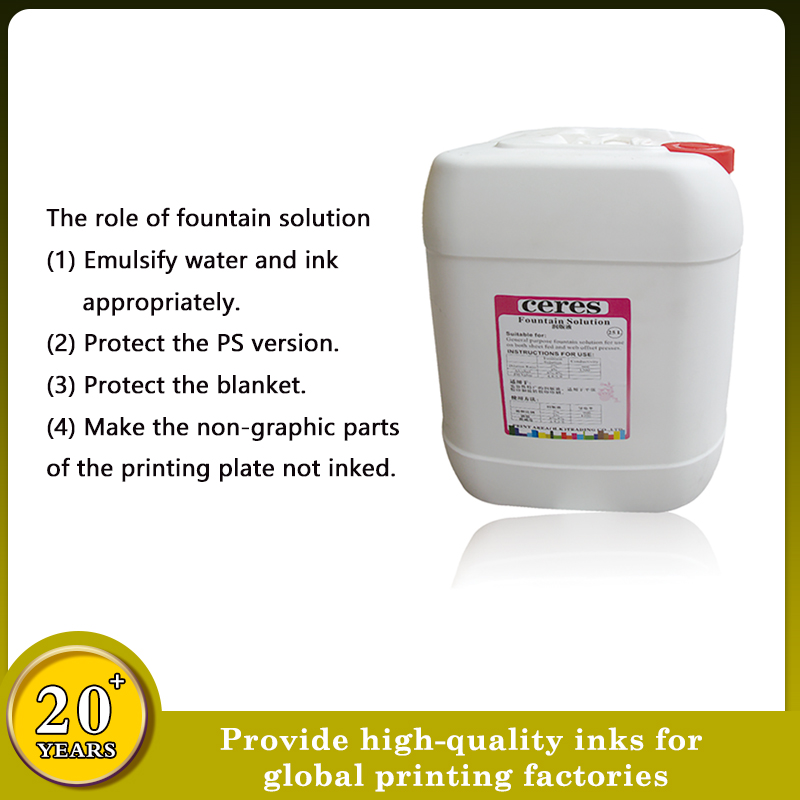

The role of fountain solution in printing:

(1) Emulsify water and ink appropriately. Due to excessive emulsification, the color paste in the ink will be diluted, causing a "water window" phenomenon in the printed product;

(2) Protect the PS version. Because the diameters of the printing plate cylinder and the blanket cylinder are sometimes not exactly the same, and their linear speeds are different during printing, the phenomenon of "dry grinding" appears at the "cut point" of the cylinder. At this time, the fountain solution has a lubricating effect and reduces the friction between the two;

(3) Protect the blanket. The friction between any objects will generate heat. Because the PS plate is made of aluminum and has a large thermal conductivity, the heat has little effect on it, while the blanket is the opposite. At this time, the function of the fountain solution is to reduce heat generation and protect the blanket;

(4) Make the non-graphic parts of the printing plate not inked. Offset printing is based on the principle of repelling oil and water. After the PS plate is exposed and developed, the surface sensing part (that is, the graphic part) can be attached to the ink, then the "dirty" phenomenon will appear at this time.

Download

Fountain Solution for Offset Printing

There are roughly 4 ingredients in fountain solution:

1. acid. It mainly enables the fountain solution to completely cover the entire PS layout to form a water film. But in fact, it is only a weak acid, because too much acidity will decompose the calcium ions in the paper, and long-term use will cause a layer of white calcium crystals to be adsorbed on the surface of the rubber roller, which will cause the ink transfer to be unsmooth;

2. Buffer. The buffering agent is mainly used to control the pH value to be kept within a certain range (usually the pH value is about 5.0). When the fountain solution is added to a certain amount, the pH value will basically stabilize at a certain value, and will not follow the dampening solution. With the increase of the plate solution, the pH value increases linearly;

3. Gum Arabic. Can protect the PS version. When the downtime is too long, it will not cause any "gray background" phenomenon on the layout;

4. Surfactant. Its role is to break the tension of the water. Promote the minimum amount of water to be thin and evenly covered on the PS plate. Therefore, many printing experts believe that if you want to print a good product, you must control the "three small":

a. The ink supply should be small. Using YT-09 high color density ink, the extremely thin ink layer can achieve the perfect performance of the field and dots at the same time;

b. The water supply for the previous version should be small. Normally printed printing plates should not see traces of water (side view printing plates);

c. The pressure between the rollers should be small. Usually we adjust the printing pressure value around 10C. The thickness of the blanket is reduced during use, and the thickness of the paper often changes, so too much pressure will inevitably increase the expansion rate of the dots and the level of the printed product is unclear.

When fountain solution is diluted, we must control three indicators:

1. pH value: The pH value required for optimal printing should be 4.5~5.5. If the acidity is too high, it will decompose the calcium ions in the paper, causing the rubber roller to absorb a layer of calcium crystals, causing the ink to be unsatisfactory; too alkaline will cause the ink to dry slowly; 2. Conductivity value: reflects the free activity of electric ions. The conductivity value standard required for printing is 1000~1300 (the conductivity value standard of alcohol dampening equipment is 800~1000). If the conductivity value is too small, it is easy to appear "dirty" on the layout; if it is too large, there will be partial inking phenomenon. When we clean the rubber rollers with car wash water, it is precisely to clean these stubborn heavy metal impurities such as magnesium ions and sodium ions (cannot be cleaned with gasoline);

3. Alcohol concentration: Adding alcohol to the fountain solution can also destroy the tension of the water, and it is volatile

At the same time, it will take away moisture and promote dryness. Usually the alcohol content is 8~12%, too little will cause foaming

Sound dampening effect; too high will make the ink dull and harmful to the health of employees. Note: wine used in printing

The essence is neither methanol nor ethanol, but isopropanol. Methanol and ethanol can increase the tree in ink

The solubility of fat makes the ink excessively emulsified.