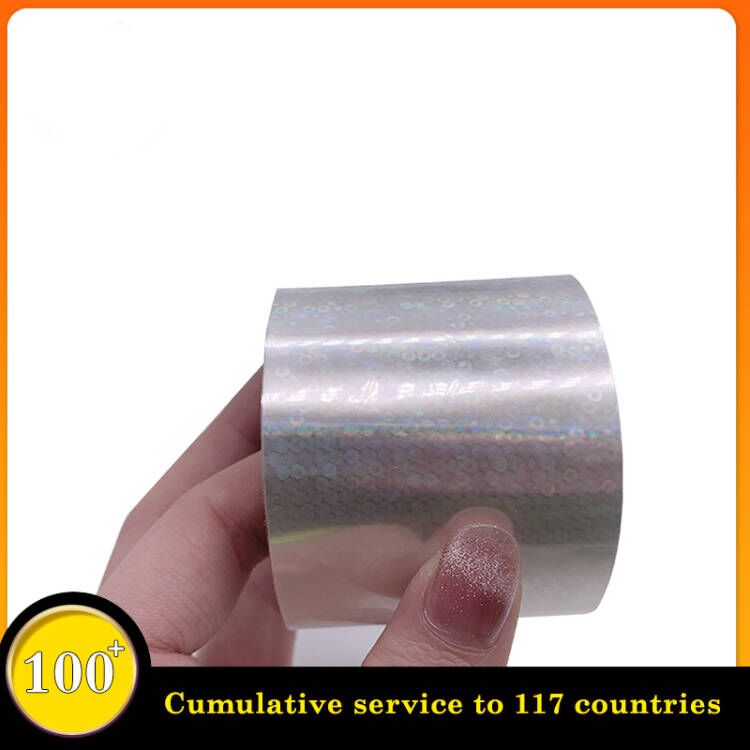

Inklove Transparent Color Dot Hot Stamping Film

Brand Ink Love

Product origin Guangdong,China

Delivery time 5-7 days

Supply capacity 100000 pcs

Hot stamping film, also known as anodized aluminum (the name of anodized aluminum is more used in the printing industry), is a hot stamping material made of a film base by coating and vacuum evaporation and adding a layer of metal foil. The thickness of anodized aluminum is generally (12, 16, 18, 20) μm, and the width is 500 to 1500 mm. The anodized aluminum foil is made by coating the release layer, the color layer on the film sheet, and then coating the adhesive layer after vacuum aluminum plating, and finally rewinding the finished product. Domestic anodized aluminum foil is generally 4 to 5 layers.

Download

hot stamping film composition

base layer

In China, 16μm thick biaxially stretched polyester film is generally used; the main function is to support the continuous action of the coating attached to the top and facilitate the hot stamping process. This means that the base film layer cannot be deformed due to the temperature rise during the hot stamping process, and should have the properties of high strength, tensile strength, and high temperature resistance.

release layer

Generally, it is mainly made of silicone resin coating. The main component of the second release layer in the anodized aluminum foil is silicone resin. Its main function is to quickly release the color material, aluminum and adhesive layer after hot stamping, whether before heating or pressing. The film is transferred to the surface of the object to be stamped, which means that there is a process in the anodized aluminum and the composition is a release layer, and the release layer contains a chemical substance (silicone resin). The main purpose is to help the transfer of substances well, and the finished hot stamping materials we have made are mainly used to stamp all kinds of hot stamping materials on various items, and also achieve printing on them. Effect. The main component in the base film layer is (polyester film). It is mainly to prevent stretching and changes during the hot stamping process, so that the hot stamping process is intact. It will not change in the slightest due to high temperature. And high strength, high temperature resistance, tensile and other properties. The release layer must have good release performance, otherwise the pictures and texts after hot stamping will be blurred, the bottom will be exposed, and the quality of the hot stamping products will be affected.

color layer

The main components of the color layer

Synthetic resins and dyes with suitable film-forming properties, heat resistance and transparency.

There are two main functions of the color layer

1. Display color.

2. Protect the aluminized layer graphic and text stamped on the surface of the item from being oxidized.

The colors of the anodized aluminum foil are orange, yellow, gray, red, green and so on according to the needs. The color of the color layer is given luster after the aluminized layer, and the color has a certain change, such as yellow is gold after aluminized, and silver after colorless aluminized. The requirements for the color layer coating are fine and free of any small particles, so as to avoid blisters and damage the uniformity of the coating.

Aluminized layer

The aluminized layer is a thin film such as a colored layer, which is placed in a vacuum chamber in a continuous aluminizing machine. Under a certain vacuum degree, through resistance heating, the aluminum wire is melted and continuously evaporated onto the color layer of the film. The main function of the aluminized layer is to reflect light, change the color properties of the color layer, and make it shiny.

adhesive layer

The adhesive layer is generally made of fusible thermoplastic resin (there are many kinds of it) on the aluminum layer through a coating machine, and the adhesive layer is formed by drying. The main function of the adhesive layer is to bond the hot stamping material to the object to be hot.

Application field

Paper industry, plastic industry, cosmetic industry, artificial leather/textile industry, 3C products & home appliances, credit card face industry, book binding industry, etc.