Offset UV Invisible Ink Red Color

Brand Ink Love

Product origin Guangdong,China

Delivery time 7-15 days

Supply capacity 1-100 ton

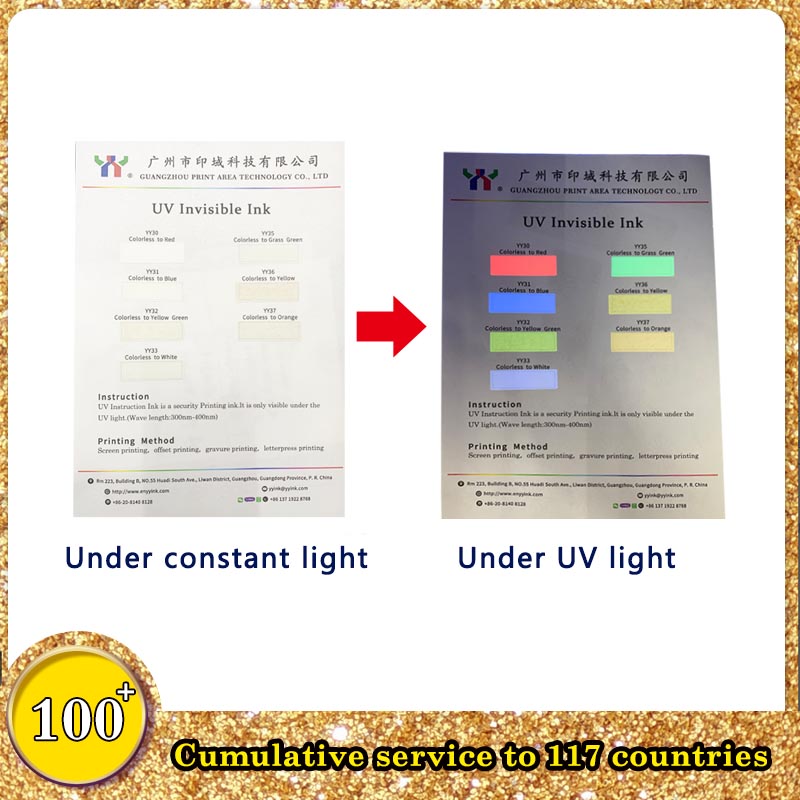

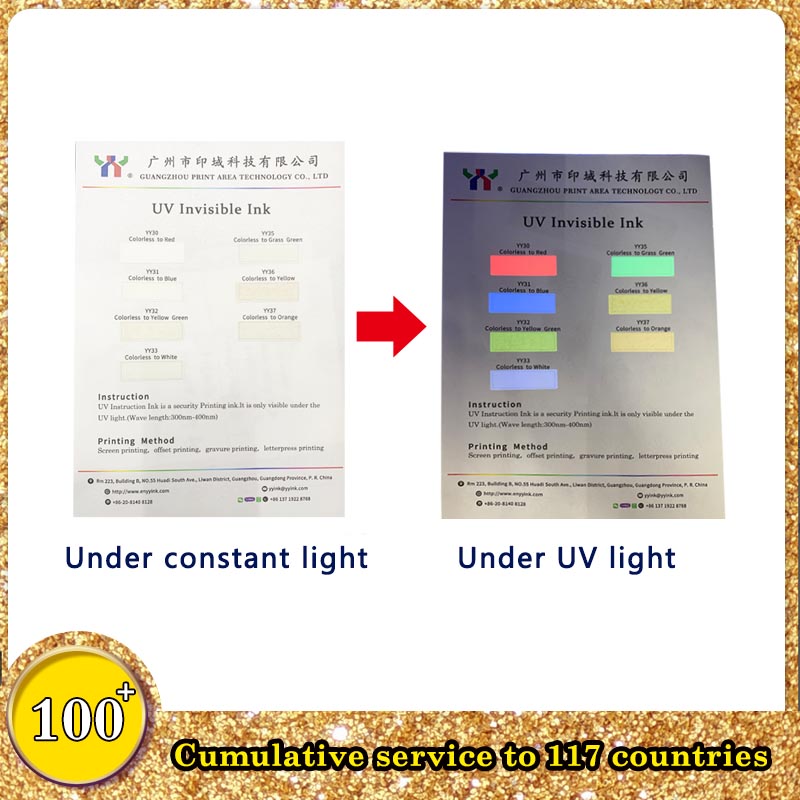

UV invisible fluorescent ink: The material used is invisible, and the printing process is simple. The ink prints invisible patterns or texts in the ultraviolet irradiation factory. Shows clear and bright fluorescent patterns. Colorful. The anti-counterfeiting detection is convenient, as long as there is an ultraviolet light source or a currency detector. Since the invisible fluorescent ink is invisible or colorless, it is invisible to the naked eye during printing, that is, without any machine-recognized tracking mark. Therefore, overprinting is more difficult, but this kind of anti-counterfeiting and concealment is better, and the anti-counterfeiting force is stronger. Most domestic medical packaging uses this kind of invisible fluorescent ink.

Tangible ultraviolet fluorescent ink: The material used is tangible fluorescent ink, the printing process is simple, the registration is accurate, and the printing effect is the same as the printing effect of ordinary ink, but under ultraviolet light, the printed matter shows abnormal brightness. At this time, it can be different from ordinary Ink.

Download

UV Invisible Ink

UV Invisible Ink Color Types:

Long wave: none-yellow, orange, red, yellow-green, emerald green, grass green, dark green, emerald blue, royal blue, black, white;

Red-orange, red-red, green-grass green, blue-grass green, orange-red, yellow-red, black-red, green-red,

Blue-red, orange-orange, blue-green, yellow-yellow, blue-blue, green-yellow-green;

Shortwave: none-yellow, orange, red, green;

Double wave: long wave red-short wave green;

Long wave blue-short wave red, short wave yellow, short wave orange, short wave green;

Long wave grass green-short wave yellow, short wave orange, short wave red.

UV Invisible Ink Usage:

Currency, bills, cards, cigarettes, alcohol, medicines, cosmetics labels, packaging, instructions and other printed matter with high anti-counterfeiting requirements.

UV Invisible Ink Printing Method:

1. Suitable for any printing method: offset printing, UV offset printing, embossing, UV flexo, screen printing, UV screen printing, water-based screen printing, pad printing, gravure, spraying, stamp ink;

2. Screen printing can be used for paper, plastic, nylon, ABS, PET, PP, metal, glass, water-based, UV and other inks. 300-350 mesh screen is recommended for screen printing.

UV Invisible Ink Additives:

1. Offset printing and embossing (generally no need to add): offset printing varnish (adjust the viscosity), white dry oil (inner dry), red dry oil (surface dry);

2. UV offset printing: UV varnishing oil

3. Gravure: butyl ester, ethyl ester, isopropanol

4. Silk screen: 718 quick-drying, 719 medium-drying, 783 slow-drying, 800 extra slow-drying, etc.

5. Silk screen ABS does not burn the bottom solvent: 815 quick-drying, 816 medium-drying, 818 slow-drying solvent

6. Water-based screen printing: special thinner (slow drying) or pure water (fast drying)

7. UV screen printing: UV screen printing thinner

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If not reached behind MOQ quantity,proofing fee will be taken by you....more