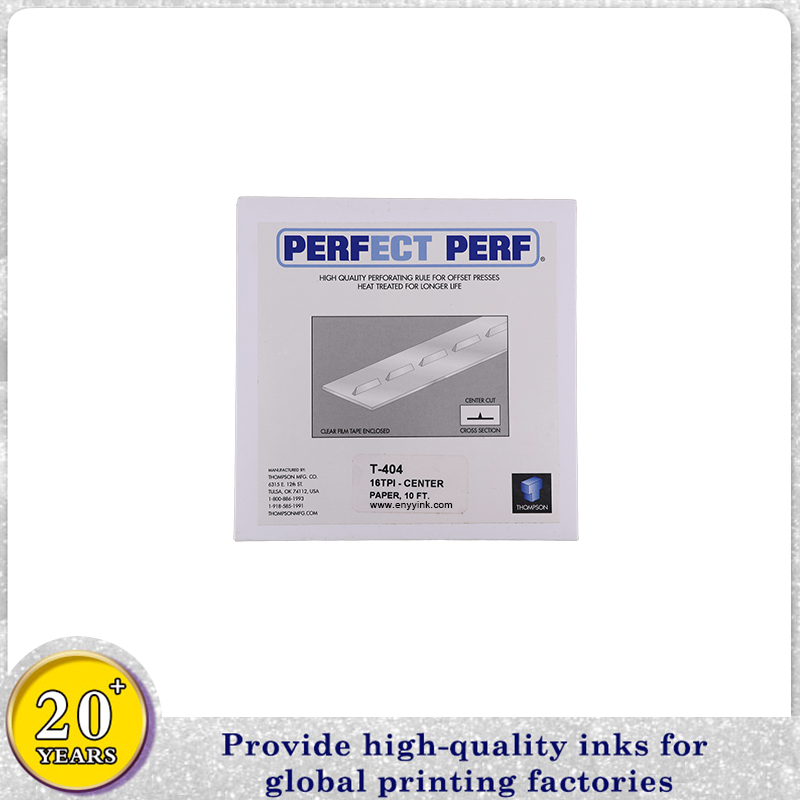

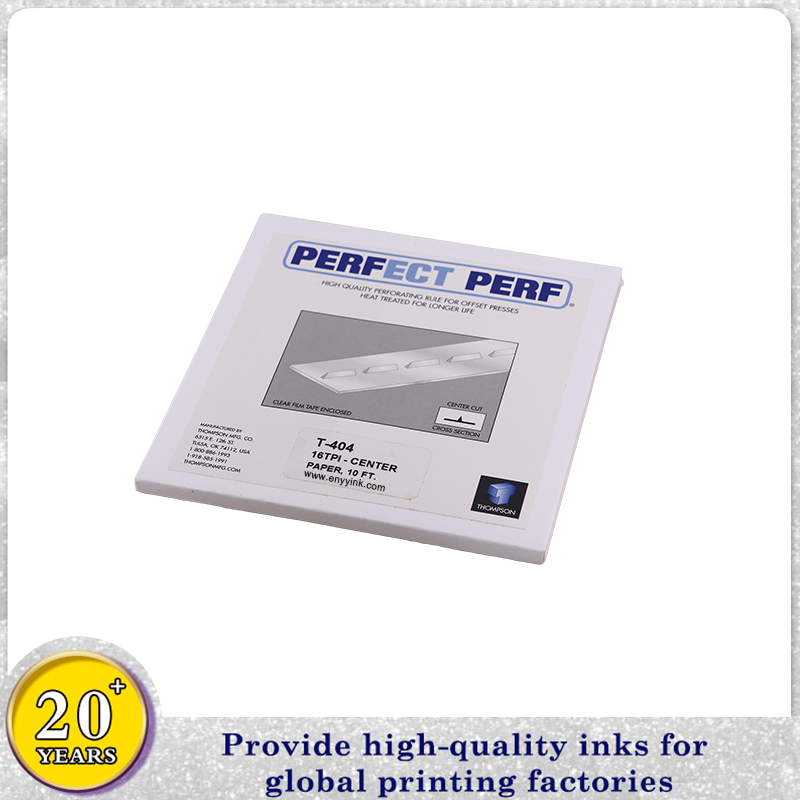

T-404 Perforating Blades for Offset Printing

Brand Perfect Perf

Product origin US

Delivery time Within 3 Days

Supply capacity 10000 pcs/Month

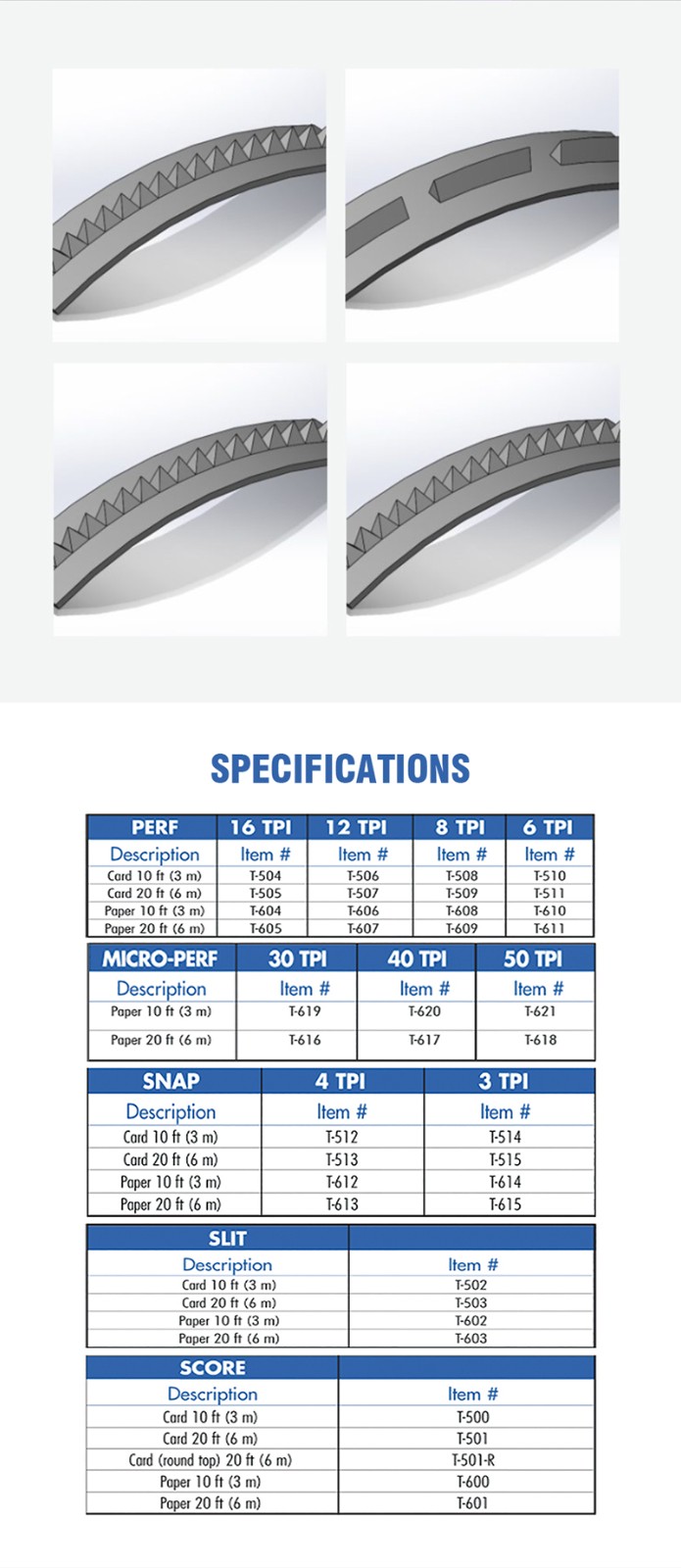

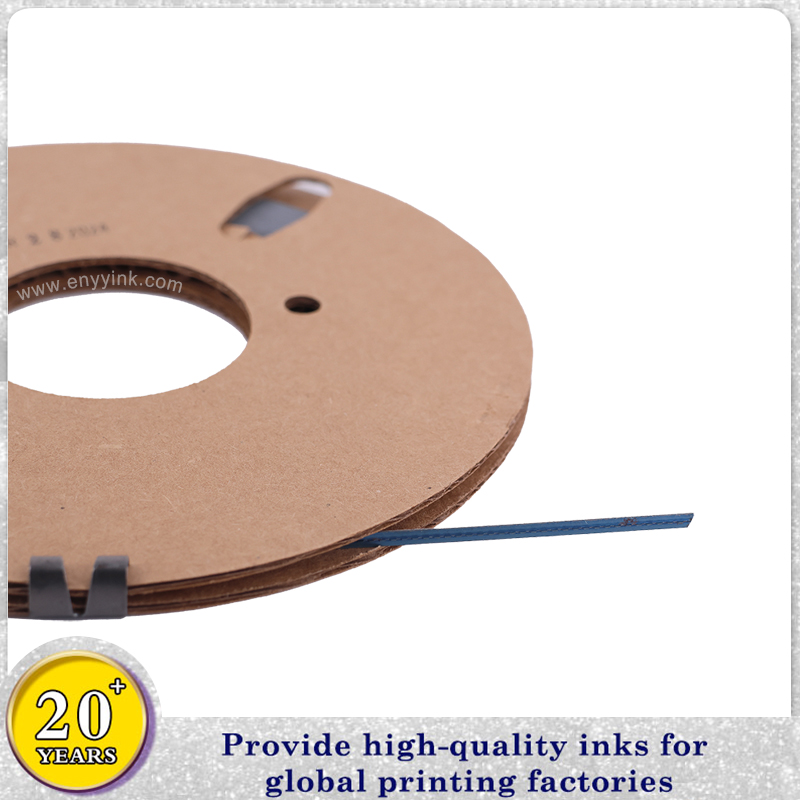

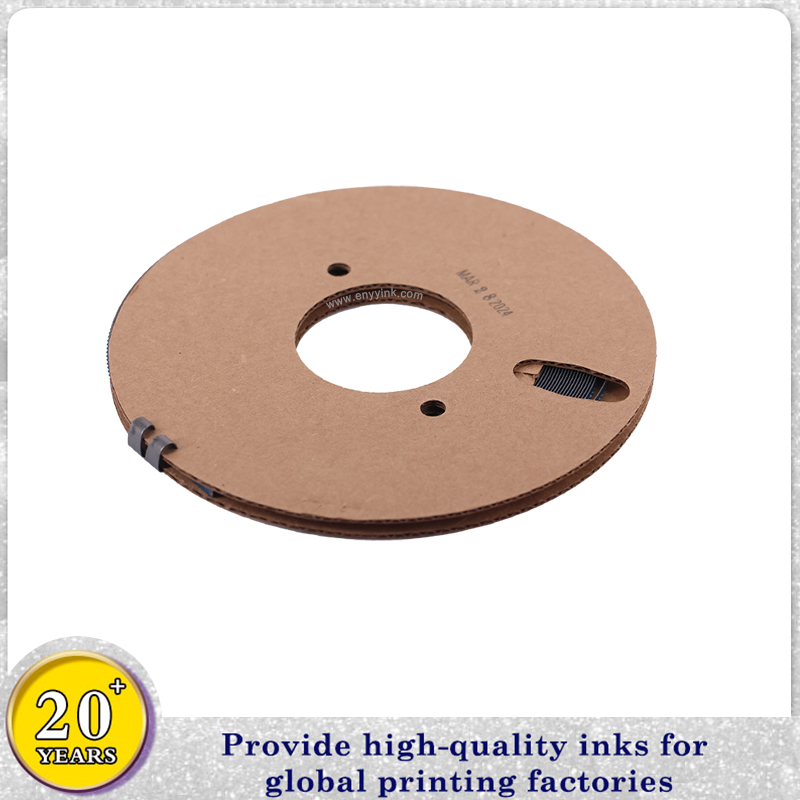

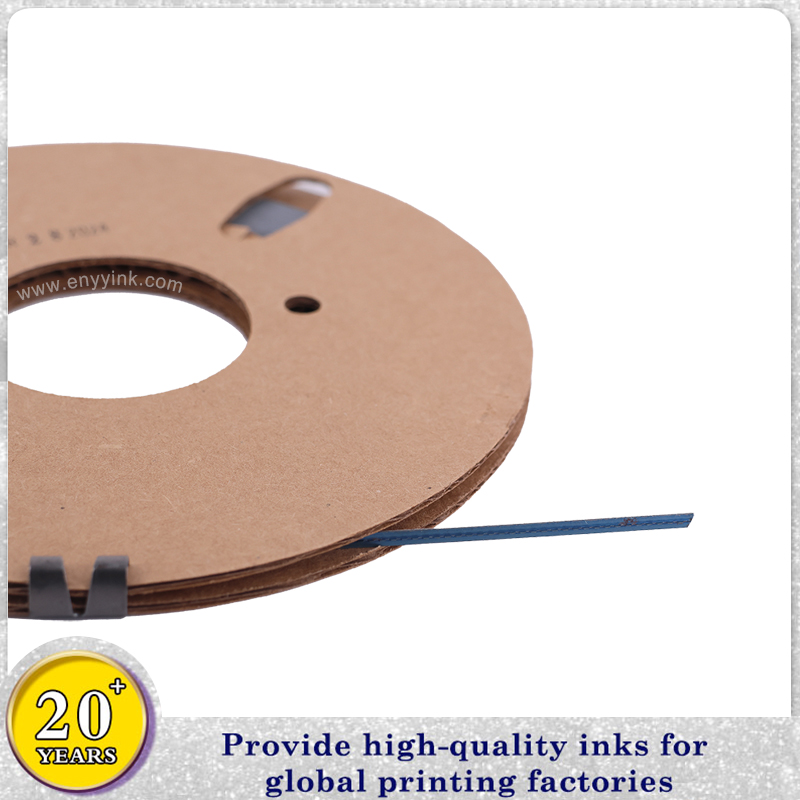

Perforating cutting rules are thin metal strips used in die cutting machines to create perforated lines on various materials. These lines of tiny perforations allow the material to be easily torn along the score without damaging the surrounding area.

Download

Perforating cutting rules are thin metal strips used in die cutting machines to create perforated lines on various materials. These lines of tiny perforations allow the material to be easily torn along the score without damaging the surrounding area.

Perforating rules are typically made from hardened steel to ensure a sharp cutting edge and long lifespan. They come in a variety of thicknesses and heights to suit different applications. The key feature of a perforating rule is the alternating pattern of teeth and gaps. The size and spacing of these teeth and gaps will determine the ease of tearing and the overall appearance of the perforated line.

Perforating cutting rules are commonly used in the following applications:

Packaging: Creating tear-off tabs on boxes, pouches, and envelopes.

Stationery: Making perforated edges on notebooks, notepads, and tickets.

Marketing materials: Creating tear-off coupons and reply cards.

Food packaging: Creating easy-open features on food packaging.

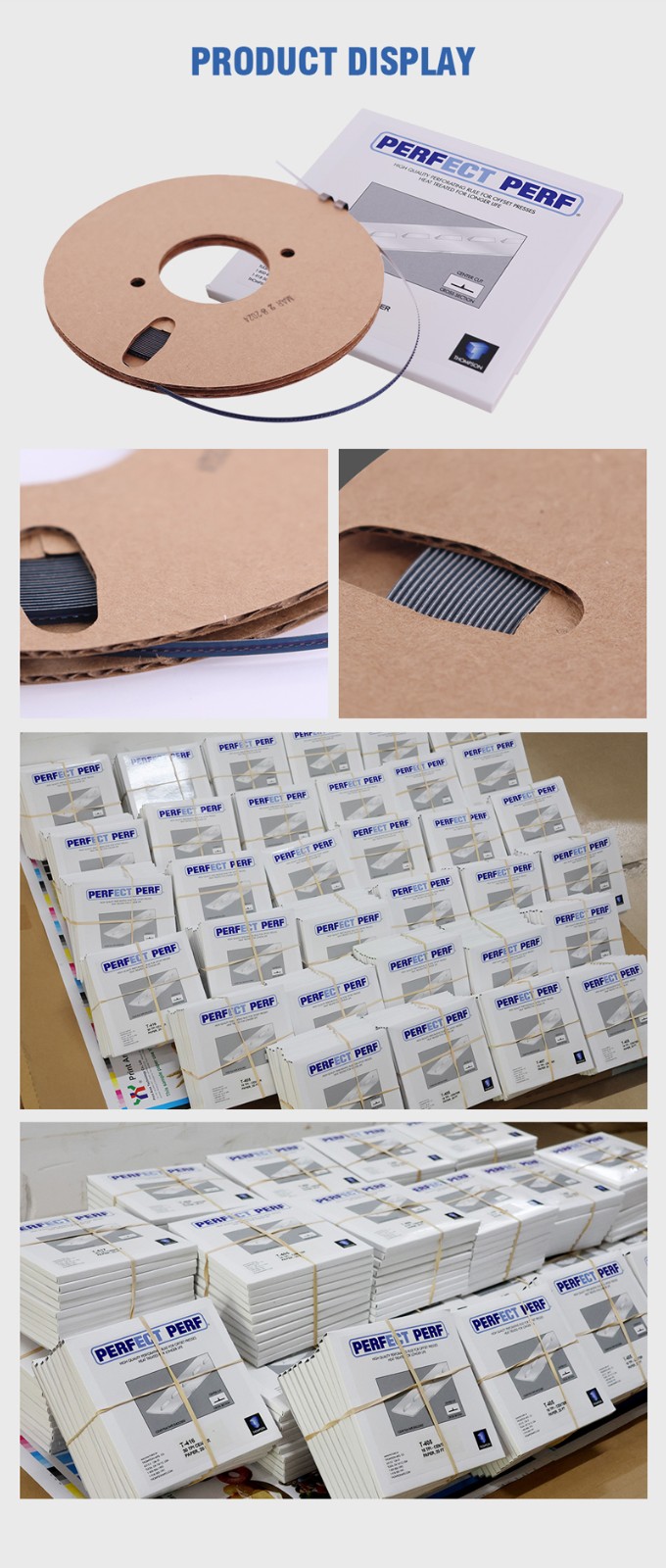

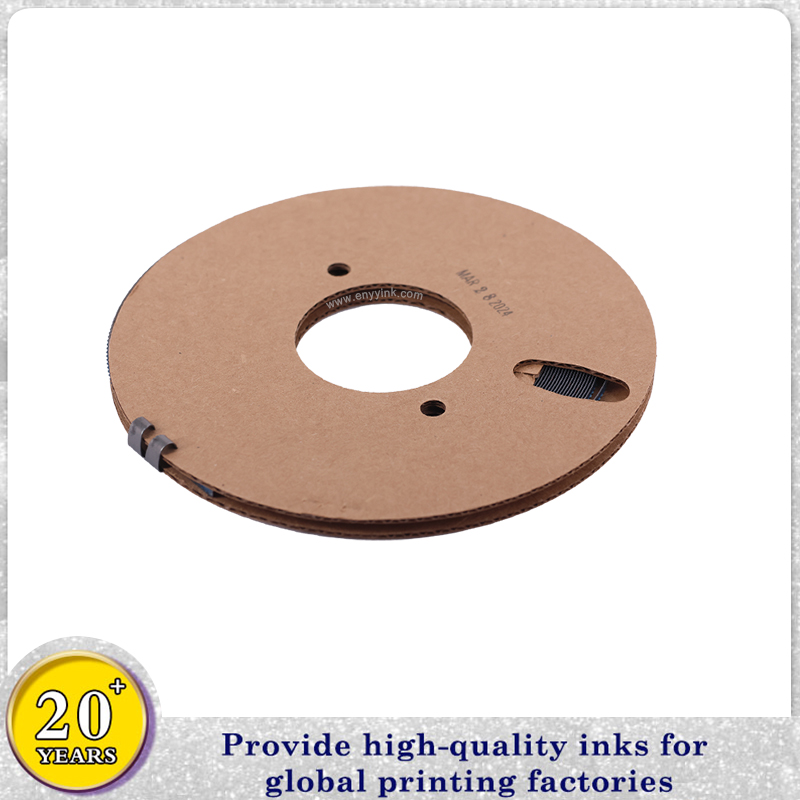

INSTRUCTIONS FOR APPLYING PERFECT PERF

NOTE:It is recommended that a good perforation guide be included in the printing plate.

STEP 1: Make certain that the impression cylinder is clean and free from oil or grease.

STEP 2: After positioning image on sheet,transfer image to the impression cylinder.

STEP 3: Cut off the amount of Perfect Perf to rule required and remove the paper backing to expose the adhesive coating.

STEP 4: Following the guideline ,apply the Perfect Perf to the impression cylinder .Once applied the adhesive wll hold the rude in position.

STEP 5: Overlay the rule with the clear film tape furnishined in the spool.On the first impression the sutting or scoring adge will puncture through the tape.

Note: After securing the rule to the cylinder ,it is advisable to reduce the pressure between the impression cylinder and gradually increase until the desired printing and perfrating results are acquired . By increasing the cyclinder pressure it will naturally improve the perforation but could affect the print quality.Therefore depending on the thickness of stock being used it may be necessary to adjust the rule height by building up the rule as suggested below.

TROUBLE-SHOOTING HINTS

If the cut is considered too light, apiece of clear film tape should be applied underneath the rule to adjust the height.Be certain to trim away any extra tape .

If the sheet will not release from the rule or if the cut is considered too heavy,another piece of clear film tape should be applied over the rule.

CAUTION: BEFORE TURNING ON THE PRESS MAKE CERTAIN THERE IS CLEARANCE BETEEN PRESS PARTS AND THE APPLIED METAL RULE.

EASY INSTRUCTIONS FOR REPEAT JOBS

Prepare the job for running the ordinary procedure.

STEP 1:Apply Perfect Perf to printed sheet or thin plastic sheet using the perforation guideline.

STEP 2:Place the sheet in the press feeder and open the sheet detectors wide enough to allow passage of the metal rule.

STEP 3:Coat the impression cylinder area behind the grippers with a generous amount of rubber ce ment. Apply a thinner coat of rubber cement on the impression cylinder over the area the sheet will cover.

STEP 4:Slowly feed the sheet through the press.As it enters the grippers turn off the press and continue the cycle by hand.

STEP 5:Cut the sheet directly behind the grippers with a sharp blade.The sheet will now stay fastened to the cylinder.Using rubber cement fasten any loose edges or corners.

STEP 6:Adjust pressure to allow for the extra sheet and your job is now ready to tun.If aplastic sheet is used it can be remored and again.