-

12-03 2022

Air Filter (2)

The filter element is the core component of the filter. It is made of special materials. It is a destructive part and requires special maintenance and maintenance;

-

11-30 2022

Offset Inks and Gravure Inks

Offset printing ink must have high viscosity (dynamic viscosity η = 40 ~ 100Pa · s). When offset printing ink spreads on the inking unit rollers or transfers to the substrate, such as printing plates and blankets, the drying components in the ink do not cause the ink to harden.

-

11-26 2022

22 Tons Ink Shipping to Europe

-

11-24 2022

Newly Renovated Print Area

-

11-18 2022

Morning Meeting Gram-Eagle Catches Chick

Eagle catching chicks is a game often played by folk children. Choose one person to be the "Eagle", the leader to be the "Hen" and the rest to be the "Chicks". , It is more suitable for playing games on grass and plastic fields. As the mother of the chicks, the hen must do her best to protect the chicks, and must not make big moves.

-

11-14 2022

Print Area Company's First Debate Competition

-

11-08 2022

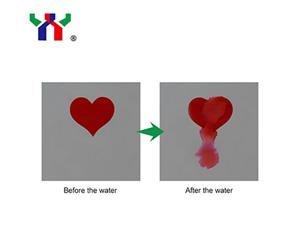

Water-sensitive Diffusion Ink

-

11-01 2022

Infrared Absorb Ink

Infrared absorbing anti-counterfeiting ink is made by adding one or several near-infrared absorbing materials into the ink, and the near-infrared absorbing material is an organic functional dye. It has absorption in the near-infrared region, the maximum absorption wavelength is 700nm~1100nm, and the oscillation wavelength falls in the near-infrared region. Because the near-infrared absorption ink absorbs infrared light, if this ink is used in a certain part of the printed product, there is no Traces, but under the detection instrument, the corresponding signal or dark graphics can be observed.

-

10-31 2022

Infrared Excitation Inks

At present, there are two kinds of infrared excitation inks, infrared red and infrared green, and there are some infrared excitation inks of different colors, such as red, green, blue, purple, etc. Infrared excitation ink is an anti-counterfeiting ink developed by adding infrared light-emitting materials to corresponding linking materials through a special process. It is colorless in appearance and emits visible light after being excited by 980nm infrared light. .

-

10-26 2022

The Basic Principle and Process of Offset Printing

The basic principle and process of offset printing Offset printing is referred to as offset printing. The printing method of offset printing is to transfer the ink dipped on the rubber surface to the paper surface through a roller-type rubber stamp. Offset printing requires less ink and molds are less expensive to manufacture than gravure. In addition, since the offset printing surface is flat and there is no concave pattern, the pattern and pattern on the printed paper surface are also flat, there is no three-dimensional sense, and the anti-counterfeiting property is poor. Now let's understand the basic principles and processes of offset printing.